-

Strong Magnet Supplier Permanent Samarium Cobalt Magnet

is also known as samarium cobalt magnet, samarium cobalt permanent magnet, samarium cobalt permanent magnet, rare earth cobalt permanent magnet, etc. It is a magnetic material made of samarium, cobalt and other metal rare earth materials through proportioning, melting into alloys, crushing, pressing and sintering. Up to 350 ℃, the negative temperature is not limited, when the working temperature is above 180 ℃, its temperature stability and chemical stability are higher than NdFeB permanent magnet materials.

One of the rare earth permanent magnets, there are mainly two components: SmCo5 and Sm2Co17.Large magnetic energy product, reliable coercivity and high temperature resistance. It is the second generation of rare earth products.

Samarium cobalt magnet (SmCo) has stronger anti-corrosion, rust-proof and high-temperature resistance than NdFeB magnets. SmCo magnets are modified by alloying, which will completely change the world’s rail transit mode.

It has strong corrosion resistance and oxidation resistance; so it is widely used in aerospace, defense and military industry, microwave devices, communications, medical equipment, instruments, meters, various magnetic transmission devices, sensors, magnetic processors, motors, magnetic cranes Wait. -

Factory Direct Price Permanent Samarium Cobalt Magnet

is also known as samarium cobalt magnet, samarium cobalt permanent magnet, samarium cobalt permanent magnet, rare earth cobalt permanent magnet, etc. It is a magnetic material made of samarium, cobalt and other metal rare earth materials through proportioning, melting into alloys, crushing, pressing and sintering. Up to 350 ℃, the negative temperature is not limited, when the working temperature is above 180 ℃, its temperature stability and chemical stability are higher than NdFeB permanent magnet materials.

One of the rare earth permanent magnets, there are mainly two components: SmCo5 and Sm2Co17.Large magnetic energy product, reliable coercivity and high temperature resistance. It is the second generation of rare earth products.

Samarium cobalt magnet (SmCo) has stronger anti-corrosion, rust-proof and high-temperature resistance than NdFeB magnets. SmCo magnets are modified by alloying, which will completely change the world’s rail transit mode.

It has strong corrosion resistance and oxidation resistance; so it is widely used in aerospace, defense and military industry, microwave devices, communications, medical equipment, instruments, meters, various magnetic transmission devices, sensors, magnetic processors, motors, magnetic cranes Wait. -

Factory Direct Price Samarium Cobalt Magnet Sm2Co17

is also known as samarium cobalt magnet, samarium cobalt permanent magnet, samarium cobalt permanent magnet, rare earth cobalt permanent magnet, etc. It is a magnetic material made of samarium, cobalt and other metal rare earth materials through proportioning, melting into alloys, crushing, pressing and sintering. Up to 350 ℃, the negative temperature is not limited, when the working temperature is above 180 ℃, its temperature stability and chemical stability are higher than NdFeB permanent magnet materials.

One of the rare earth permanent magnets, there are mainly two components: SmCo5 and Sm2Co17.Large magnetic energy product, reliable coercivity and high temperature resistance. It is the second generation of rare earth products.

Samarium cobalt magnet (SmCo) has stronger anti-corrosion, rust-proof and high-temperature resistance than NdFeB magnets. SmCo magnets are modified by alloying, which will completely change the world’s rail transit mode.

It has strong corrosion resistance and oxidation resistance; so it is widely used in aerospace, defense and military industry, microwave devices, communications, medical equipment, instruments, meters, various magnetic transmission devices, sensors, magnetic processors, motors, magnetic cranes Wait. -

Factory Direct Sell Customized Samarium Cobalt Magnet Sm2Co17

is also known as samarium cobalt magnet, samarium cobalt permanent magnet, samarium cobalt permanent magnet, rare earth cobalt permanent magnet, etc. It is a magnetic material made of samarium, cobalt and other metal rare earth materials through proportioning, melting into alloys, crushing, pressing and sintering. Up to 350 ℃, the negative temperature is not limited, when the working temperature is above 180 ℃, its temperature stability and chemical stability are higher than NdFeB permanent magnet materials.

One of the rare earth permanent magnets, there are mainly two components: SmCo5 and Sm2Co17.Large magnetic energy product, reliable coercivity and high temperature resistance. It is the second generation of rare earth products.

Samarium cobalt magnet (SmCo) has stronger anti-corrosion, rust-proof and high-temperature resistance than NdFeB magnets. SmCo magnets are modified by alloying, which will completely change the world’s rail transit mode.

It has strong corrosion resistance and oxidation resistance; so it is widely used in aerospace, defense and military industry, microwave devices, communications, medical equipment, instruments, meters, various magnetic transmission devices, sensors, magnetic processors, motors, magnetic cranes Wait. -

Customized Samarium Cobalt Magnet Sm2Co17

is also known as samarium cobalt magnet, samarium cobalt permanent magnet, samarium cobalt permanent magnet, rare earth cobalt permanent magnet, etc. It is a magnetic material made of samarium, cobalt and other metal rare earth materials through proportioning, melting into alloys, crushing, pressing and sintering. Up to 350 ℃, the negative temperature is not limited, when the working temperature is above 180 ℃, its temperature stability and chemical stability are higher than NdFeB permanent magnet materials.

One of the rare earth permanent magnets, there are mainly two components: SmCo5 and Sm2Co17.Large magnetic energy product, reliable coercivity and high temperature resistance. It is the second generation of rare earth products.

Samarium cobalt magnet (SmCo) has stronger anti-corrosion, rust-proof and high-temperature resistance than NdFeB magnets. SmCo magnets are modified by alloying, which will completely change the world’s rail transit mode.

It has strong corrosion resistance and oxidation resistance; so it is widely used in aerospace, defense and military industry, microwave devices, communications, medical equipment, instruments, meters, various magnetic transmission devices, sensors, magnetic processors, motors, magnetic cranes Wait. -

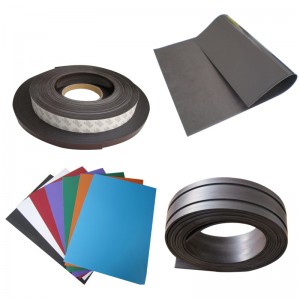

Factory Wholesale Rubber Magnets With Customized Service

Physical Property

Operating temperature: – 26°C to 80℃ Hardness: 30-45 Density: 3.6-3.7 Tensile strength: 25-35 Elongation at break and flexural properties: 20-50 Environmental protection: environmental protection of raw materials, in line with EN71, RoHS and ASTM, etc -

Bonded NdFeB Magnets

Bonded NdFeB, composed of Nd2Fe14B, is a synthetic magnet. Bonded NdFeB magnets are magnets made by “press molding” or “injection molding” by mixing quick-quenched NdFeB magnetic powder and binder. Bonded magnets have high dimensional accuracy, can be made into magnetic components with relatively complex shapes, and have the characteristics of one-time molding and multi-pole orientation. Bonded NdFeB has high mechanical strength, and can be formed at one time with other supporting components.

Bonded magnets appeared around the 1970s when SmCo was commercialized. The market situation of sintered permanent magnets is very good, but it is difficult to precisely process them into special shapes, and they are prone to cracking, damage, edge loss, corner loss and other problems during the processing. In addition, they are not easy to assemble, so their application is limited. To solve this problem, the permanent magnets are pulverized, mixed with plastic, and pressed into a magnetic field, which is probably the most primitive manufacturing method of bonded magnets. Bonded NdFeB magnets have been widely used due to their low cost, high dimensional accuracy, large freedom of shape, good mechanical strength, and light specific gravity, with an annual growth rate of 35%. Since the emergence of NdFeB permanent magnet powder, flexible bonded magnets have achieved rapid development due to its high magnetic properties. -

AlNiCo Magnets

AlNiCo permanent magnet is an alloy composed of metal aluminum, nickel, cobalt, iron and other trace metal elements.

-

High Performance Customized Samarium Cobalt Magnet SmCo

is also known as samarium cobalt magnet, samarium cobalt permanent magnet, samarium cobalt permanent magnet, rare earth cobalt permanent magnet, etc. It is a magnetic material made of samarium, cobalt and other metal rare earth materials through proportioning, melting into alloys, crushing, pressing and sintering. Up to 350 ℃, the negative temperature is not limited, when the working temperature is above 180 ℃, its temperature stability and chemical stability are higher than NdFeB permanent magnet materials.

One of the rare earth permanent magnets, there are mainly two components: SmCo5 and Sm2Co17.Large magnetic energy product, reliable coercivity and high temperature resistance. It is the second generation of rare earth products.

Samarium cobalt magnet (SmCo) has stronger anti-corrosion, rust-proof and high-temperature resistance than NdFeB magnets. SmCo magnets are modified by alloying, which will completely change the world’s rail transit mode.

It has strong corrosion resistance and oxidation resistance; so it is widely used in aerospace, defense and military industry, microwave devices, communications, medical equipment, instruments, meters, various magnetic transmission devices, sensors, magnetic processors, motors, magnetic cranes Wait. -

High Quality Ferrite Magnet Y10Y25Y33

Ferrite is a ferrimagnetic metal oxide. In terms of electrical properties, the resistivity of ferrite is much larger than that of elemental metal or alloy magnetic materials, and it also has higher dielectric properties. The magnetic properties of ferrites also show that they have high permeability at high frequencies. Therefore, ferrite has become a non-metallic magnetic material widely used in the field of high frequency weak current. Due to the low magnetic energy stored in the unit volume of ferrite, the saturation magnetic induction (Bs) is also low (usually only 1/3~1/5 of pure iron), which limits its use in low frequencies requiring higher magnetic energy density.

-

30-year Factory Wholesale Neodymium Magnet

NdFeB is simply a magnet. Unlike the magnets we usually see, it is called “Magnetic King” because of its excellent magnetic properties. NdFeB contains a large amount of rare earth elements neodymium, as well as iron and boron, which are hard and brittle.

As a rare earth permanent magnet material, NdFeB has extremely high magnetic energy product and coercive force. At the same time, the advantages of high energy density make NdFeB permanent magnet materials widely used in modern industry and electronic technology. It is possible to reduce the size, weight and thickness of equipment such as instruments, electroacoustic motors, and magnetic separation and magnetization.