|

Product Name:

|

Neodymium Magnet, NdFeB Magnet

|

|

|

Grade & Working Temperature: |

Grade

|

Working Temperature

|

|

N30-N55

|

+80℃ / 176℉

|

|

|

N30M-N52M

|

+100℃ / 212℉

|

|

|

N30H-N52H

|

+120℃ / 248℉

|

|

|

N30SH-N50SH

|

+150℃ / 302℉

|

|

|

N25UH-N50UH

|

+180℃ / 356℉

|

|

|

N28EH-N48EH

|

+200℃ / 392℉

|

|

|

N28AH-N45AH

|

+220℃ / 428℉

|

|

|

Coating:

|

Ni, Zn, Au, Ag, Epoxy, Passivated, etc..

|

|

|

Application:

|

Sensors, motors, filter automobiles, magnetic holders, loudspeakers, wind generators, medical equipment, etc.

|

|

|

Advantage:

|

If in stock, free sample and deliver at same day; Out of stock, delivery time is same with mass production

|

|

Neodymium Magnet Catalogue

Rectangle, rod, counterbore, cube, shaped, disc, cylinder, ring, sphere, arc, trapezoid, etc.

Neodymium magnet series

Ring neodymium magnet

NdFeB square counterbore

Disc neodymium magnet

Arc shape neodymium magnet

NdFeB ring counterbore

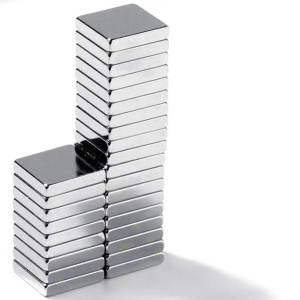

Rectangular neodymium magnet

Block neodymium magnet

Cylinder neodymium magnet

The magnetization direction of the magnet is determined during the fabrication process. The magnetization direction of the finished product cannot be changed. Please be sure to specify the desired magnetization direction of the product.

Coating and Plating

What are the common coatings of NdFeB magnets?

NdFeB strong magnet coating is generally nickel, zinc, epoxy resin and so on. Depending on the electroplating, the color of the magnet surface will also be different, and the storage time will also vary for a long time.

The effects of NI, ZN, epoxy resin, and PARYLENE-C coatings on the magnetic properties of NdFeB magnets in three solutions were studied by comparison. The results showed that: in acid, alkali, and salt environments, polymer material coatings The protection effect on the magnet is the best, the epoxy resin is relatively poor, the NI coating is second, and the ZN coating is relatively poor:

Zinc: The surface looks silvery white, can be used for 12-48 hours of salt spray, can be used for some glue bonding, (such as AB glue) can be stored for two to five years if it is electroplated.

Nickel: looks like stainless steel, the surface is difficult to be oxidized in the air, and the appearance is good, the gloss is good, and the electroplating can pass the salt spray test for 12-72 hours. Its disadvantage is that it cannot be used for bonding with some glue, which will cause the coating to fall off. Accelerate the oxidation, now the nickel-copper-nickel electroplating method is mostly used in the market for 120-200 hours of salt spray.

Production Flow

Packing

Packaging details: magnetically insulated packaging, foam cartons, white boxes and iron sheets, which can play a role in shielding magnetism during transportation.

When it comes to transporting goods that are sensitive to magnetism, it is important to take measures to ensure that the products are protected from any magnetic interference. This not only keeps the products safe but also ensures their quality.

Delivery details: Within 7-30 days after order confirmation.

FAQ

Feel free to contact us !

We are thrilled to extend a warm welcome to all our clients and partners who are interested in exploring our manufacturing business. With over 20 years of experience, we take pride in delivering high-quality products that exceed the expectations of our customers.

We have a team of experts who ensure that our manufacturing processes are in line with industry standards and regulations. Our production facilities are well-equipped with modern technology and equipment that enables us to offer efficient and effective solutions to our customers.

In conclusion, we are a reputable manufacturer with a proven track record of success in the industry. We welcome you to visit us and experience our commitment to excellence firsthand. Thank you for considering us as your manufacturing partner, and we look forward to doing business with you.