Grades of Neodymium Magnet

|

Product Name:

|

Neodymium Magnet, NdFeB Magnet

|

|

|

Grade & Working Temperature: |

Grade

|

Working Temperature

|

|

N30-N55

|

+80℃ / 176℉

|

|

|

N30M-N52M

|

+100℃ / 212℉

|

|

|

N30H-N52H

|

+120℃ / 248℉

|

|

|

N30SH-N50SH

|

+150℃ / 302℉

|

|

|

N25UH-N50UH

|

+180℃ / 356℉

|

|

|

N28EH-N48EH

|

+200℃ / 392℉

|

|

|

N28AH-N45AH

|

+220℃ / 428℉

|

|

|

Coating:

|

Ni, Zn, Au, Ag, Epoxy, Passivated, etc..

|

|

|

Application:

|

Neodymium magnets are useful for multiple applications. From creative crafting & DIY projects to exhibition displays, furniture making, packaging boxes, school classroom decor, home and office organizing, medical, science equipment and much more. They are also used for various design & engineering and manufacturing applications where small sized, maximum strength magnets are required. .

|

|

|

Advantage:

|

If in stock, free sample and deliver at same day; Out of stock, delivery time is same with mass production

|

|

Neodymium Magnet Catalogue

We can also custom neodymium magnets according to your exact specifications, just send us a special request and we'll help you determine the most cost effective solution for your project .

Iregular special shape series

Ring neodymium magnet

NdFeB square counterbore

Disc neodymium magnet

Arc shape neodymium magnet

NdFeB ring counterbore

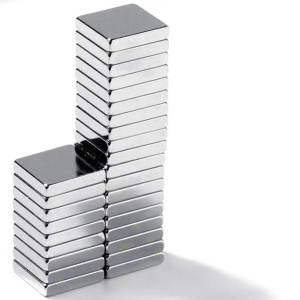

Rectangular neodymium magnet

Block neodymium magnet

Cylinder neodymium magnet

About mangetic direction

Isotropic magnets have the same magnetic properties in any direction and attract together arbitrarily.

Anisotropic permanent magnetic materials have various magnetic properties in different directions, and the direction in which they can obtain the best/strongest magnetic properties is called the orientation direction of permanent magnetic materials.

Orientation technology is a necessary process for producing anisotropic permanent magnet materials. The new magnets are anisotropic. The magnetic field orientation of powder is one of the key technologies for manufacturing high-performance NdFeB magnets. Sintered NdFeB is generally pressed by magnetic field orientation, so the orientation direction needs to be determined before production, which is the preferred magnetization direction. Once a neodymium magnet is made, it cannot change the direction of magnetization. If it is found that the magnetization direction is wrong, the magnet needs to be re-customized.

Coating and Plating

Neodymium magnets are a composition of mostly Neodymium, Iron and Boron. If left exposed to the elements, the iron in the magnet will rust. To protect the magnet from corrosion and to strengthen the brittle magnet material, it is usually preferable for the magnet to be coated. There are a variety of options for coatings, but nickel is the most common and usually preferred. Our nickel plated magnets are actually triple plated with layers of nickel, copper, and nickel again. This triple coating makes our magnets much more durable than the more common single nickel plated magnets. Some other options for coating are zinc, tin, copper,epoxy,silver and gold. Our gold plated magnets are actually quadruple plated with nickel, copper, nickel and a top coating of gold.

Packing details

FAQ

Q. How can we guarantee quality?

A: -All of our products complies the ROHS and REACH standards and are certified by IAFT16949 and SGS.

-After production, our technician will provide you with BH curves, including Br, Hcj, Hcb, squareness, grade, and so on according to your requirement.

-We are suppliers of Yiheda, ABB, and other Fortune 500 companies.

Q.What can you buy from us?

A: Neodymium Magnets (NdFeB), magnetic gear, magnetic couplings, multiple-pole magnetic rings, Ferrite Magnets, Smco Magnets,Alnico Magnets, Magnetic Assembly, and solutions.

Q. Why should you buy from us not from other suppliers?

A:-Direct manufacturer, we can provide the most affordable price and the most flexible customization.

-Quality guaranteed: IAFT16949 and SGS.

-Global service: Till now, we have exported to more than 60 countries,68.81% in Asia, 21.27% in Europe, 7.99% in North America, and others.

-Leading technology: Hot-pressed magnets, Nano coating, low weight loss technology, low temp coefficient, laminated technology,etc.

Q. What information do we need to provide if I want a quotation?

A:Dear friend, if needed, please kindly help us to know the following details,The grade, size, surface treatment, quantity, and whether Magnetizing. if you have drawing,will be very helpful.

We can do any customized service, so pls share your drawing if you have one as well.