Product Details

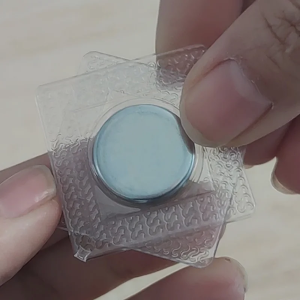

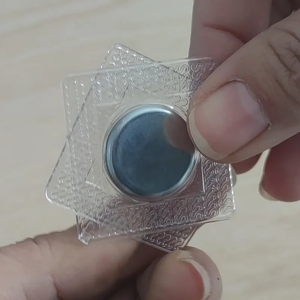

| Product Name | Single side magnet |

| Grade | N28-N42 |

| Size of magnet | D8-D20mm, can custom according to customer's request |

| Magnetization direction | Thickness or Sides magnetization |

| Coating | Zinc |

| Certifications | ISO9001, CE, TS16949, ROHS, SGS, etc |

| Samples | Available |

Packing Details

Shipping Way

Neodymium Disk Magnet Round Magnet Customization

|

Product Name:

|

Neodymium Magnet, NdFeB Magnet

|

|

|

Grade & Working Temperature: |

Grade

|

Working Temperature

|

|

N30-N55

|

+80℃ / 176℉

|

|

|

N30M-N52M

|

+100℃ / 212℉

|

|

|

N30H-N52H

|

+120℃ / 248℉

|

|

|

N30SH-N50SH

|

+150℃ / 302℉

|

|

|

N25UH-N50UH

|

+180℃ / 356℉

|

|

|

N28EH-N48EH

|

+200℃ / 392℉

|

|

|

N28AH-N45AH

|

+220℃ / 428℉

|

|

|

Coating:

|

Ni, Zn, Au, Ag, Epoxy, Passivated, etc..

|

|

|

Application:

|

Sensors, motors, filter automobiles, magnetic holders, loudspeakers, wind generators, medical equipment, etc.

|

|

|

Advantage:

|

If in stock, free sample and deliver at same day; Out of stock, delivery time is same with mass production

|

|

Neodymium Magnet Catalogue

Form:

Rectangle, rod, counterbore, cube, shaped, disc, cylinder, ring, sphere, arc, trapezoid, etc.

Neodymium magnet series

Ring neodymium magnet

NdFeB square counterbore

Disc neodymium magnet

Arc shape neodymium magnet

NdFeB ring counterbore

Rectangular neodymium magnet

Block neodymium magnet

Cylinder neodymium magnet

Various Shapes

Any size and performance can be customized according to requirements

The highest accuracy can reach 0.01mm

▼

The magnetization direction of the magnet is determined during the fabrication process. The magnetization direction of the finished product cannot be changed. Please be sure to specify the desired magnetization direction of the product.

Coating and Plating

Sintered NdFeB is easily corroded, because the neodymium in sintered NdFeB will be oxidized when exposed to the air, which will eventually cause sintered NdFeB product powder to foam, which is why the periphery of sintered NdFeB needs to be coated with anti-corrosion Oxide layer or electroplating, this method can protect the product well and prevent the product from being oxidized by air.

Common electroplating layers of sintered NdFeB include zinc, nickel, nickel-copper-nickel, etc. Passivation and electroplating are required before electroplating, and the degree of oxidation resistance of different coatings is also different.