Specification

These super strength magnets provide you with countless possibilities as they are ideal for various purposes. Use them in order to Hang Heavy Objects And Complete Educational, Science, Home Improvement And DIY Projects ,They also are great for industrial application.

1. Material

The raw materials are Nd, Fe and B. Starting from the selection of materials, high-quality neodymium-iron-boron magnets are produced with high-quality rare-earth materials and various mixed materials.

2. Tolerance

Using advanced slicing and wire cutting equipment, professional skilled operators are allowed to control the product's normal tolerance to +/-0.05mm.

3. Coating

Has a variety of conventional Ni-Cu-Ni, Zn, black epoxy coating. after plating, has a good rust, corrosion resistance. Corrosion resistance: black epoxy> Ni-Cu-Ni > Zn

4. Durable

High remanence, high coercivity, anti-demagnetization, permanent use.

5. Size

The products is can accept customized , so the size it depend on you. what do you need size ? we can do it .

Neodymium Magnet Catalogue

Iregular special shape series

Ring neodymium magnet

NdFeB square counterbore

Disc neodymium magnet

Arc shape neodymium magnet

NdFeB ring counterbore

Rectangular neodymium magnet

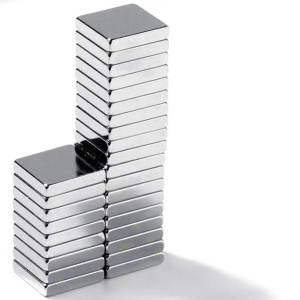

Block neodymium magnet

Cylinder neodymium magnet

About mangetic direction

Isotropic magnets have the same magnetic properties in any direction and attract together arbitrarily.

Anisotropic permanent magnetic materials have various magnetic properties in different directions, and the direction in which they can obtain the best/strongest magnetic properties is called the orientation direction of permanent magnetic materials.

Orientation technology is a necessary process for producing anisotropic permanent magnet materials. The new magnets are anisotropic. The magnetic field orientation of powder is one of the key technologies for manufacturing high-performance NdFeB magnets. Sintered NdFeB is generally pressed by magnetic field orientation, so the orientation direction needs to be determined before production, which is the preferred magnetization direction. Once a neodymium magnet is made, it cannot change the direction of magnetization. If it is found that the magnetization direction is wrong, the magnet needs to be re-customized.

Coating and Plating

Zinc coating

Silver white surface, suitable for surface appearance and anti oxidation requirements are not particularly high, can be used for general glue bonding (such as AB glue).

Plate with nickel

The surface of stainless steel color, anti-oxidation effect is good, good appearance gloss, internal performance stability. It has along service life and can pass the 24-72h salt spray test.

Gold-plated

The surface is golden yellow, which is suitable for appearance visibility occasions such as gold crafts and gift boxes.

Epoxy coating

Black surface, suitable for harsh atmospheric environment and high requirements of corrosion protection occasions, can pass 12-72h salt spray test.

Packing details

FAQ