Grades of Neodymium Magnet

|

Product Name:

|

Neodymium Magnet, NdFeB Magnet

|

|

|

Grade & Working Temperature: |

Grade

|

Working Temperature

|

|

N30-N55

|

+80℃ / 176℉

|

|

|

N30M-N52M

|

+100℃ / 212℉

|

|

|

N30H-N52H

|

+120℃ / 248℉

|

|

|

N30SH-N50SH

|

+150℃ / 302℉

|

|

|

N25UH-N50UH

|

+180℃ / 356℉

|

|

|

N28EH-N48EH

|

+200℃ / 392℉

|

|

|

N28AH-N45AH

|

+220℃ / 428℉

|

|

|

Coating:

|

Ni, Zn, Au, Ag, Epoxy, Passivated, etc..

|

|

|

Application:

|

Neodymium magnets are useful for multiple applications. From creative crafting & DIY projects to exhibition displays, furniture making, packaging boxes, school classroom decor, home and office organizing, medical, science equipment and much more. They are also used for various design & engineering and manufacturing applications where small sized, maximum strength magnets are required. .

|

|

|

Advantage:

|

If in stock, free sample and deliver at same day; Out of stock, delivery time is same with mass production

|

|

Neodymium Magnet Catalogue

We can also custom neodymium magnets according to your exact specifications, just send us a special request and we'll help you determine the most cost effective solution for your project .

Our stock basic geometric shapes in various thicknesses and premium grades ranging from N25 to N52. Finishing options include uncoated or with a triple-coated (Ni-Cu-Ni) shiny nickel finish for optimal protection against corrosion. Not all of our magnets are shown on this website so please contact us today if you don't see what you are looking for.

Iregular special shape series

Ring neodymium magnet

NdFeB square counterbore

Disc neodymium magnet

Arc shape neodymium magnet

NdFeB ring counterbore

Rectangular neodymium magnet

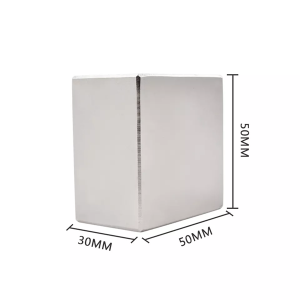

Block neodymium magnet

Cylinder neodymium magnet

Orientation technology is a necessary process for producing anisotropic permanent magnet materials. The new magnets are anisotropic. The magnetic field orientation of powder is one of the key technologies for manufacturing high-performance NdFeB magnets. Sintered NdFeB is generally pressed by magnetic field orientation, so the orientation direction needs to be determined before production, which is the preferred magnetization direction. Once a neodymium magnet is made, it cannot change the direction of magnetization. If it is found that the magnetization direction is wrong, the magnet needs to be re-customized.

Coating and Plating

Zinc coating

Silver white surface, suitable for surface appearance and anti oxidation requirements are not particularly high, can be used for general glue bonding (such as AB glue).

Plate with nickel

The surface of stainless steel color, anti-oxidation effect is good, good appearance gloss, internal performance stability. It has along service life and can pass the 24-72h salt spray test.

Gold-plated

The surface is golden yellow, which is suitable for appearance visibility occasions such as gold crafts and gift boxes.

Epoxy coating

Black surface, suitable for harsh atmospheric environment and high requirements of corrosion protection occasions, can pass 12-72h salt spray test.

Packing details

FAQ

Q: Are you trading company or manufacturer ?

A: We are a 20 years factory.

Q: How long is your delivery time?

A: Generally it is 3 -5 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us .